ABOUT OUR ORGANIZATION

We’re working to create a strong U.S. industrial base for hybrid electronics manufacturing – with our member community of companies, academic institutions, non-profits, and government partners – through three operational areas: our manufacturing consortium, our Technology Hub, and our education and workforce development programs. These three areas allow us to establish and grow the manufacturing industrial base, advance technology and fabrication, and secure human capital to create the workforce of the future.

HYBRID ELECTRONICS Network

Learn more about our member community and how you can get involved with the network through project calls, roadmapping activities, events, and more.

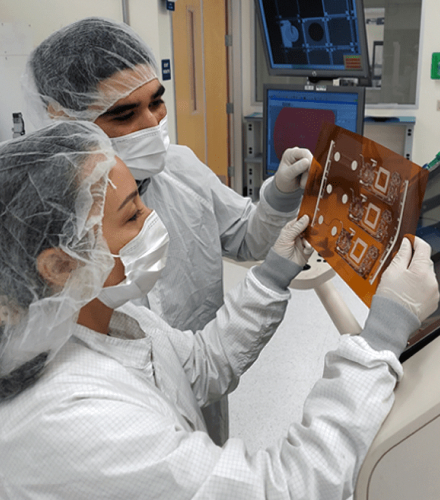

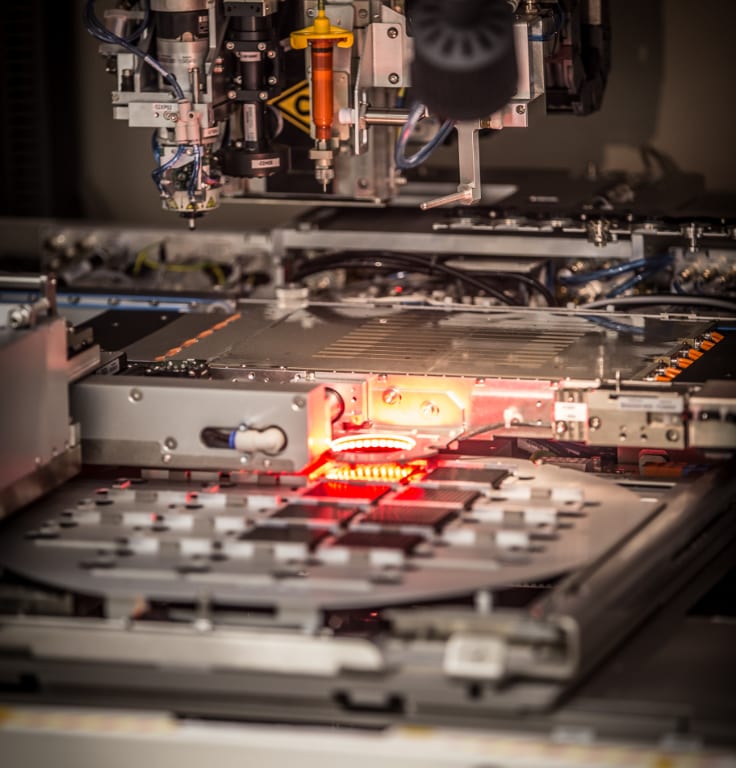

Engineering & Fab Services

Learn more about how you can benefit from a collaborative approach to electronics design, development and problem-solving via our state-of-the-art Technology Hub.

Education & Workforce Development

Learn more about our portfolio of programs that leverage our position in the advanced manufacturing and printed flexible electronics spaces to address critical gaps in the progression of talent through the labor market.