An Interview with Eisuke Tsuyuzaki of Bayflex Solutions LLC

Question: Eisuke, would you please tell us about your role at Bayflex Solutions LLC and the focus of your organization?

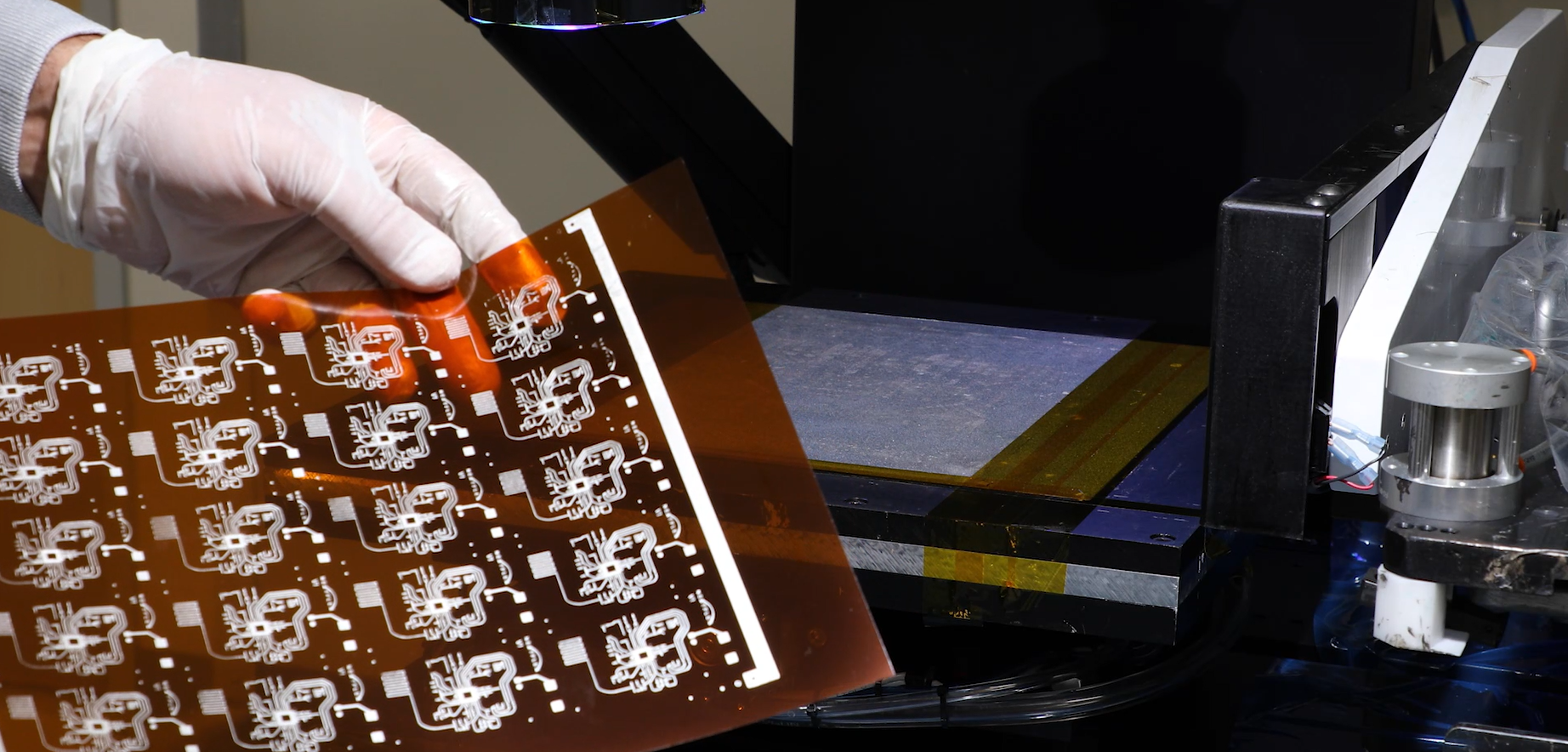

Answer: I am a founder & Managing Partner of Bayflex Solutions. Our organization, based in San Jose, is a developer of a lab automation & data analytics platform that is dedicated to flexible & printed electronics. I myself tend to focus on outward activities; listening to customers and guiding our development teams on products (AI based testing tools) & systems (extreme condition mechanical integration) and nurturing partnerships across the supply ecosystem.

Q: Bayflex Solutions is a newer member of NextFlex. What drew you to the FHE manufacturing community and what are you hoping to accomplish through your membership?

A: Actually, Bayflex Solutions has collaborated with NextFlex since 2017 by providing a wide range of mechanical jigs to better understand the unique needs of continuous long-term testing synchronized with sensors, meters, optics, environments & analytics. Building on this experience, we have recently partnered up with a number of leading member institutions and enterprises, which has enabled us to accelerate and broaden our support to the industry. We simply hope to do more of the same.

Q: What is a key innovation that will enable widespread adoption of FHE and related technologies, and what application areas are you working in?

A: Bayflex Solutions fundamentally believes that reliability data in R&D and Manufacturing are essential to ensure “good enough” material, component, and device development at scale, and enable intelligent electronics everywhere. We have been successful in collaborating with leading consumer electronics companies to develop flexible displays based upon de jure and de facto standards and having these capabilities across a global supply chain. We hope to support and kick-start a similar process for advanced manufacturing using flexible electronic components in medical, mobility and logistics applications.

Q: What upcoming activities are you most excited about?

A: Folks ask and expect us to focus on our best idea, to integrate Artificial Intelligence into our platform. So, for us, it’s about unleashing exponential productivity enhancements. In the near term, Flexdata.ai is about workforce training & development; enabling an accredited individual access to the latest best practice testing processes but also assist to run these tests remotely perhaps even with robotics integration. In the medium term, we are working on automatic anomaly detection with predictive analysis with various optical, infra-red, x-ray or even CT images for even faster material assessments or product qualification.

Q: In what ways do you think NextFlex and hybrid electronics can impact microelectronics manufacturing and / or your own product development?

A: It goes without saying that NextFlex has been instrumental to the development of America’s Hybrid Electronics industries. However, we are reaching a critical moment, where we need to broaden the tent with even more participants and by extending outwards, demonstrate and communicate our shared capabilities to those in “traditional” microelectronics industries. We go further when we go together.