Success Story: THE BOEING COMPANY AND GEORGIA INSTITUTE OF TECHNOLOGY’S FLEXIBLE ANTENNA ARRAY TECHNOLOGY (FAAT)

Overview

The Boeing Company and its partners the Georgia Institute of Technology (Georgia Tech), had a vision to build flexible antenna arrays using advanced flexible hybrid electronics (FHE) manufacturing. They partnered with NextFlex, a Manufacturing Innovation Institute with the shared goal of advancing U.S. manufacturing of FHE, to help develop mature multilayer patterning technologies for array antennas.

NextFlex’s Role

NextFlex provided funding support, technology insight and guidance to Boeing and Georgia Tech to produce printed carbon nanotubes and flexible ferrites, an array withsurface adherence, flexible electronic packaging and low crosstalk feed technology. The partners tested the performance of antennas at various bends and environmental conditions to generate radio frequency (RF) data on printed transmission lines, a printed assembly of packaged low-noise amplifier (LNA) and printed magnetic film to ensure optimal coverage.

By combining expertise in FHE and advanced manufacturing, the partners developed a process to print antenna elements and a microstrip feed network on flexible hybrid substrates without verticalinterconnect access greatly reducing fabrication time and costs. These multilayer antenna arrays include positive, negative, positive sourcing (PnP) electronics, patterned ferrites, environmental coatings to protect the arrays from harsh conditions and flex diodes and interconnects (ICs) to help the antennas transmit and receive signals from various angles. Collaboration between these companies initiated a fundamental foundation for advancement in FHE.

Benefits

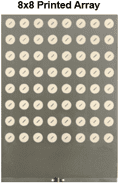

With NextFlex’s support, Boeing and Georgia Tech were able to collaborate to take the developed FHE antenna design and fabrication methods and create 2×2, 4×4 and 8×8 printed panel antenna arrays. They have been able to respond to the accelerated adoption of wireless and FHE technologies in the digital aerial navigation era, moving towards the launch of FHE “skins” for UAVs to be used in advanced commercial and military applications.

For more information, please contact info@nextflex.us