TECHNICAL CAPABILITIES

NextFlex’s team of engineers can help you with mechanical design, electrical design, design for manufacturing (DFM), and simulation. We have experience with novel design methods for RF and antenna printing.

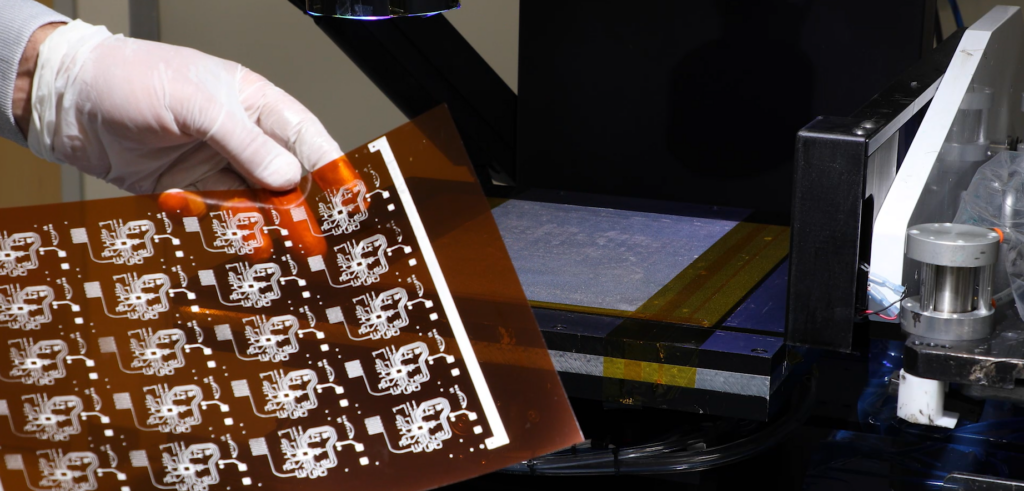

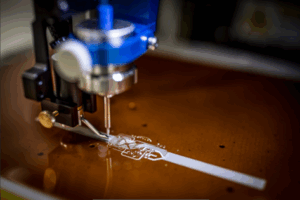

In the NextFlex Print Lab, you have access to machines for screen, inkjet, aerosol jet, gravure offset, and extrusion printing with materials like silver, silver – silver chloride (Ag/AgCl), copper, or carbon inks, to substrates up to 200 x 300 mm (8” x 12”) including PET, PI, TPU, and biodegradable paper-like substrates.

The NextFlex Assembly Lab gives you access to machines for die attach methods including flip chip, pads up for wire bond (or printed) interconnects, and packaged (WLCSP) components; encapsulation; and surface mount technology (SMT, tape and reel pick-and-place), including multiple dispense processes with multiple types of adhesives.

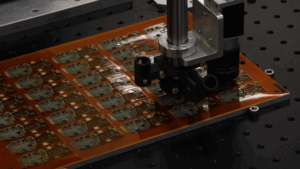

Using laser processing equipment, NextFlex can help you with via drilling, laser ablation, substrate marking, and singulation.

NextFlex’s Test Lab has tools for a large variety of testing for electrical including RF and signal generation, for mechanical including stretch, fold, twist, and shear, and for environmental testing including temperature cycling, temperature and humidity, and sun exposure.

We can help you streamline your manufacturing processes, allowing you to reduce cost and maximize efficiency.

NextFlex engineers can help you with application development for iOS, Android, Windows, and more.

NextFlex can manufacture small-scale runs of your devices to prove manufacturability and help understand needs for scaling up production.

Application Areas

With a rapid push toward fly by wire and unmanned platforms, the aerospace industry has sought a variety of technological developments to impact communication systems, navigation & surveillance systems, flight control & management systems, mission/tactical systems, and electrical & emergency systems. And because the enabling technology must be streamlined for speed and light-weight for cost, hybrid electronics finds itself front and center in the evolution of the industry. Similarly, the use of Unmanned Aerial Vehicles (UAV) in commercial applications for monitoring, surveying and mapping, precision agriculture, and aerial remote sensing is resulting in even greater increased demand for hybrid electronics components.

From the 77GHz radar range-finding for automotive, to electronic warfare systems to wideband satellite communications to 5G connectivity, or BTLE enabled wearable electronics, or IOT protocols like SigFox and LORA or even true mesh networks, RF is one area where hybrid electronics growth continues to accelerate. As a result of this escalating demand for radio frequency components and innovative materials used in manufacturing these devices, NextFlex is playing a lead role in multiple segments within the RF and communications space building everything from NFC and BTLE devices, to complex AESA structures for electronic warfare.

Hybrid Electronics is enabling ultrathin and flexible, wearable electronics that can sample biomarkers in sweat, tears, saliva and interstitial fluid as well as conventional skin surface sensors. Through new ways to manufacture wearable electronics, intelligent devices, and integrated sensor fusion approaches, printed hybrid electronics are enabling medical quality data that ties to gold standards in the medical community. These new devices and wearable electronics encompass a broad range of products addressing both consumer and industrial applications and include everything from sports and activity trackers, to healthcare monitors, smart clothing, watches and glasses, and wearable 3D motion trackers.

As vehicles continue to get smarter and more electronically complex, new challenges are being introduced throughout the development process. Factor in consumer preference considerations and increasing safety requirements, plus the need for savvy and skilled electronics design, prototyping and pilot scale manufacturing capabilities are growing within the automotive PCB market. Early hybrid electronics applications are addressing everything from Advanced Driver Assistance Systems (ADAS) and basic automotive safety components that utilize FHE, to body comfort and vehicle lighting and powertrain systems.

Soft robotics are enabling high adaptability and flexibility for accomplishing routine tasks in addition to the improved safety when working with, and around, humans especially in a manufacturing environment. Robotic exoskeletons designed for giving mobility back to those who have lost it and/or assisting with moving and lifting objects to reduce workplace injury are prime examples of early soft robotic applications. Similarly, assistive soft robotics are proving useful to first responders and medical technicians for providing safer and better handling of patients and incapacitated individuals.

HEALTH MONITORING

As infrastructure ages and complex systems such as commercial airlines require increased maintenance to keep them operational, intelligent systems that can trigger maintenance and improvements based on the actual state of wear have become essential. These newly developed asset monitoring solutions are able to monitor the structural integrity of everything from bridges, buildings, dams, levees, tunnels and other civil infrastructure, to aircraft, wind turbines, and other large structures. The asset monitoring market includes applications impacting civil infrastructure, aerospace & defense, energy, mining, and industrial machinery, automotive, transportation, and marine structures.

Success Stories

Learn about some of NextFlex’s completed projects.

WORKING WITH NEXTFLEX

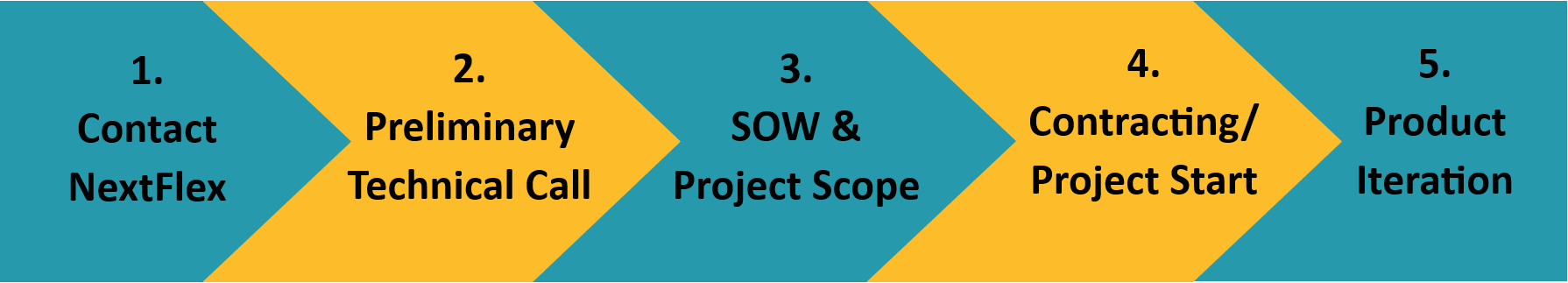

Our process:

- Identify your organization’s needs, contact NextFlex, and secure an NDA with our legal team.

- Take advantage of a preliminary call with our technical team to discuss how we can help you meet your needs.

- Develop a Statement of Work and Project Scope with our technical team. This helps generate a timeline and set expectations for the course of the project.

- If you already have a product design, contract with our team to have your product developed. If you have a concept but no design, our team can help you translate your ideas into design files that are ready for manufacturing. If you are looking for funding or manufacturing partners, join a teaming event and submit a proposal for our next Project Call. Throughout the contracting process, you can rest assured that your Intellectual Property is secure with our robust IP policy.

- Iterate with our team as your project needs change.

We can help you by:

- Mentoring/assisting qualified small- and medium-sized manufacturers, including providing engineering and design services.

- Supporting small business recipients in prototyping & developing proof of concept demonstrations for DoD projects.

- Helping organizations de-risk technology/capital equipment adoption by enabling the evaluation of tool capabilities that exist at the NextFlex technology hub for their applications prior to investing in new equipment.

- Providing manufacturing support from early prototype through low-volume manufacturing (if appropriate).

- Assisting with transitioning/scaling of production to a U.S. volume manufacturer.

Tell us how we can help by completing this form or sending an inquiry to info@nextflex.us:

Virtual Tour

Explore the NextFlex Technology Hub with this interactive virtual tour

With funding from the Air Force Research Laboratory (AFRL) and support from the maintenance team at Warner-Robbins Air Force Base, NextFlex developed a next generation Flexible Hybrid Electronics (FHE) confined space monitoring device. The device is designed as a flexible conformal armband capable of monitoring volatile organic compound concentrations, oxygen levels, temperature and humidity. Processing and communication are provided by a Bluetooth radio that can connect to a cell phone and allows for remote monitoring of the worker from a central control station. The design is powered by an onboard battery which can be wirelessly recharged using an embedded Qi charging circuit and brings together an incredibly dense array of features into a highly flexible, wearable and robust additively manufactured electronics format.

With funding from the Air Force Research Laboratory (AFRL) and support from the maintenance team at Warner-Robbins Air Force Base, NextFlex developed a next generation Flexible Hybrid Electronics (FHE) confined space monitoring device. The device is designed as a flexible conformal armband capable of monitoring volatile organic compound concentrations, oxygen levels, temperature and humidity. Processing and communication are provided by a Bluetooth radio that can connect to a cell phone and allows for remote monitoring of the worker from a central control station. The design is powered by an onboard battery which can be wirelessly recharged using an embedded Qi charging circuit and brings together an incredibly dense array of features into a highly flexible, wearable and robust additively manufactured electronics format. The Boeing Company and its partners the Georgia Institute of Technology (Georgia Tech), had a vision to build flexible antenna arrays using advanced flexible hybrid electronics (FHE) manufacturing. They partnered with NextFlex, a Manufacturing Innovation Institute with the shared goal of advancing U.S. manufacturing of FHE, to help develop mature multilayer patterning technologies for array antennas.

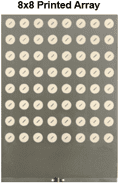

The Boeing Company and its partners the Georgia Institute of Technology (Georgia Tech), had a vision to build flexible antenna arrays using advanced flexible hybrid electronics (FHE) manufacturing. They partnered with NextFlex, a Manufacturing Innovation Institute with the shared goal of advancing U.S. manufacturing of FHE, to help develop mature multilayer patterning technologies for array antennas. The partners tested the performance of antennas at various bends and environmental conditions to generate radio frequency (RF) data on printed transmission lines, a printed assembly of packaged low-noise amplifier (LNA) and printed magnetic film to ensure optimal coverage.

The partners tested the performance of antennas at various bends and environmental conditions to generate radio frequency (RF) data on printed transmission lines, a printed assembly of packaged low-noise amplifier (LNA) and printed magnetic film to ensure optimal coverage. These multilayer antenna arrays include positive, negative, positive sourcing (PnP) electronics, patterned ferrites, environmental coatings to protect the arrays from harsh conditions and flex diodes and interconnects (ICs) to help the antennas transmit and receive signals from various angles. Collaboration between these companies initiated a fundamental foundation for advancement in FHE.

These multilayer antenna arrays include positive, negative, positive sourcing (PnP) electronics, patterned ferrites, environmental coatings to protect the arrays from harsh conditions and flex diodes and interconnects (ICs) to help the antennas transmit and receive signals from various angles. Collaboration between these companies initiated a fundamental foundation for advancement in FHE. General Electric quickly recognized that wearables are increasingly becoming the future of both the technology and health sectors. With this forethought in mind, GE Global Research partnered with Binghamton University, the Rochester Institute of Technology, Infinite Corridor Technologies and NextFlex to develop a revolutionary, ubiquitous sensor systems for medical devices and to help combat the key fundamental challenges of integrating stretchable printed leads in wearables.

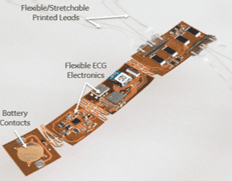

General Electric quickly recognized that wearables are increasingly becoming the future of both the technology and health sectors. With this forethought in mind, GE Global Research partnered with Binghamton University, the Rochester Institute of Technology, Infinite Corridor Technologies and NextFlex to develop a revolutionary, ubiquitous sensor systems for medical devices and to help combat the key fundamental challenges of integrating stretchable printed leads in wearables. NASA developed a next-generation wearable flexible sensor array for astronaut crew health monitoring, also known as “AstroSense”. Multi-disciplinary teams from Marshall Space Flight Center, Ames Research Center, and Flight Surgeons at Johnson Space Center all collaborated with NextFlex to design a wearable sensor array aimed at monitoring astronaut’s health and vital levels in space.

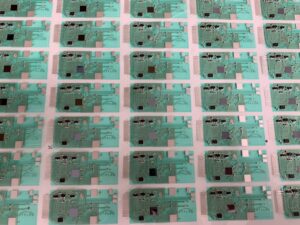

NASA developed a next-generation wearable flexible sensor array for astronaut crew health monitoring, also known as “AstroSense”. Multi-disciplinary teams from Marshall Space Flight Center, Ames Research Center, and Flight Surgeons at Johnson Space Center all collaborated with NextFlex to design a wearable sensor array aimed at monitoring astronaut’s health and vital levels in space.

Profusa had a vision for its Lumee™ Oxygen Platform to be used in patients with potential acute and/or chronic changes in tissue oxygen levels who may benefit from continuous monitoring. Before it could be commercially available, Profusa had a key issue to resolve with the wearable reader of its injectable hydrogel sensor.

Profusa had a vision for its Lumee™ Oxygen Platform to be used in patients with potential acute and/or chronic changes in tissue oxygen levels who may benefit from continuous monitoring. Before it could be commercially available, Profusa had a key issue to resolve with the wearable reader of its injectable hydrogel sensor.